Who we are

Our history

The company was founded in 1977 in Sansepolcro (AR) as a small activity and only a few years after its foundation it becomes a reality already known in the field at national level. At the beginning of the 80’s a new larger facility is built to meet the demands of constantly growing customers.

Since the end of the 80’s the business leadership tends to make a product with a high qualitative and technological content, engaging the resources resulting from its growth in the purchase of equipments with which is realized the first laboratory for the controls.

In 1991, its continuous expansion also leads to the acquisition of Tecfond in Turin.

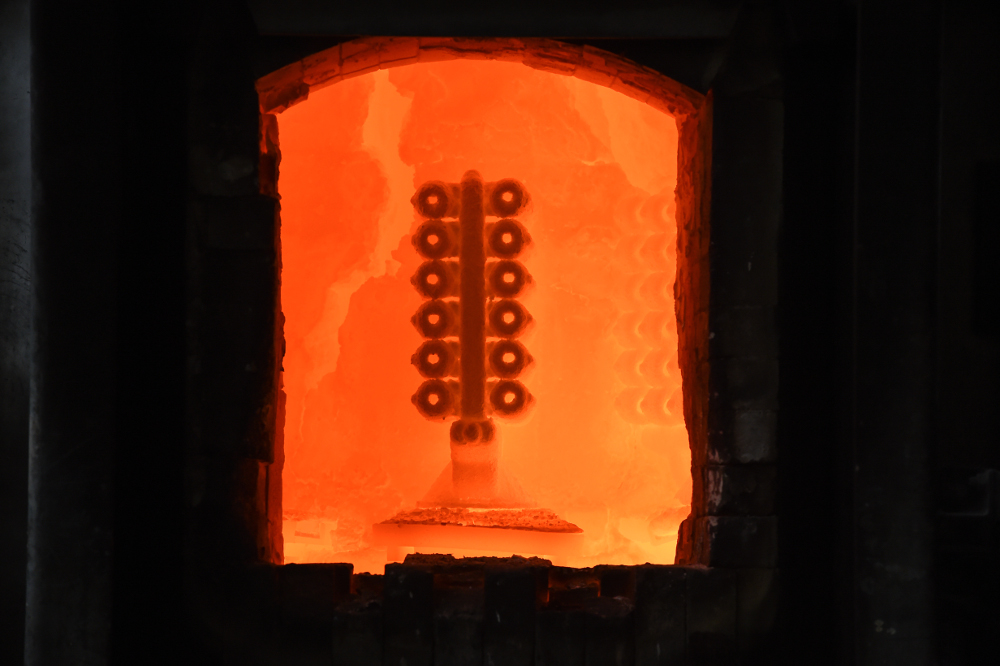

In 1996 a new project takes shape with the construction of a new plant next to the existing one, with additional 5000 square meters covered where the equipment for the vacuum melting is installed.

In 1999, the attention to improve continuously its production process pushes the Founderia Biagiotti to reach the ISO certification.

In 2001 the construction of the new department with CAD-CAM machining center 5-axis represents an important step in the realization of moulds for castings with increasingly complex geometries.

The steady presence at all major fairs of the sector pushes towards an internationalization process that leads the foundry to stand out in the European market.

The new system of vacuum melting operating since 2000 constantly increases its know-how by investing the own resources on the study and experimentation of the use of new alloys.

Why to choose us?

We provide high quality products and a service of excellence, creating an activ working relationship with our customers helping them to meet all their needs.

We aim to continually make our services more flexible, basing ourselves in a technological leadership, ensuring a continuous business growth of our know-how.

We guarantee our staff a safe and gratifying work environment where it is possible to develop their full potential.

Domestic products certification

Each step of the production process is monitored step by step by qualified personnel according to specific protocols starting from procurement of the input material to the final inspection of the product.

All castings are traceable to the melting batch and during the acquisition of each new order a manufacturing and testing plan according to the technical characteristics of the castings and to the specifications required by the customer is established.

The chemical analysis of the melting batch is provided for each casting according to specific control EN 10204 3.1 and visual control, the dimensional control is made during sampling phase, furthermore on the customer’s request the following checks can be carried out:

- Radioscopy and Radiography

- Liquid penetrant testing

- Hardness

- Metallography

List of main reference standards:

UNI EN 1369

UNI EN 1371-1

UNI EN 1559-1

UNI EN 10283

UNI EN 10349

UNI EN ISO 8062-1-3

UNI EN 10293

UNI EN 1559-5

UNI EN 10295

UNI EN 1559-2

UNI EN 10204